Production line configuration

1. Multi-layer co-extrusion blown film production line

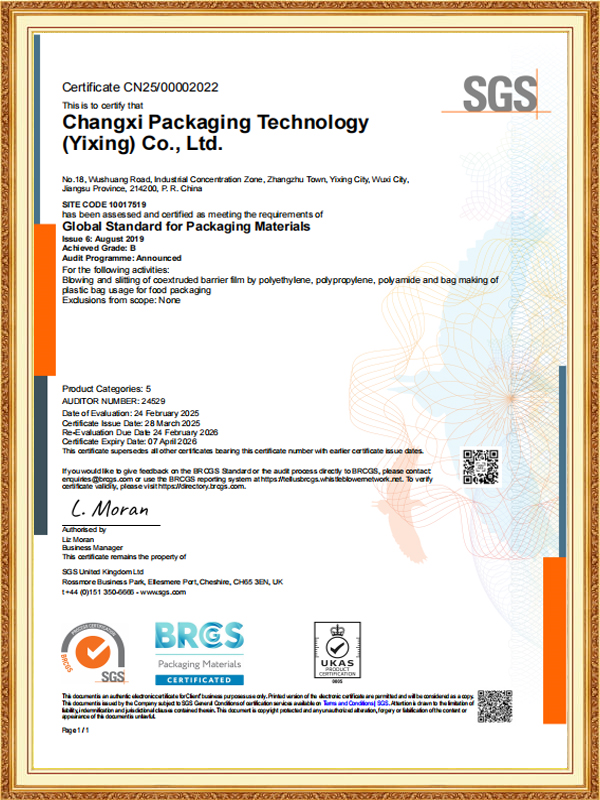

In order to meet the market's diverse needs for PE Easy-to-peel No-residue Lid Film, Changsha Packaging Technology (Yixing) Co., Ltd has introduced 4 multi-layer co-extrusion blown film production lines. These production lines use advanced co-extrusion technology to extrude multiple layers of film of different materials at the same time, thus giving the packaging film a variety of properties, such as barrier properties, heat resistance, easy peeling and no residue. By precisely controlling the proportion and thickness of each layer of material, the company can produce packaging films that meet the specific requirements of different customers.

2. High-speed slitting unit

In the production process, the high-speed slitting unit plays a vital role. Changxi Packaging Technology (Yixing) Co., Ltd is equipped with several high-speed slitting units, which can slit the blown film with extremely high precision and speed to ensure the accuracy and consistency of product size. The unit also has the function of flexibly adjusting the slitting width to meet customers' different requirements for packaging film size.

3. Fully automatic bag making production line

In order to further improve production efficiency and product quality, the company has also introduced a fully automatic bag making production line. The production line integrates film conveying, heat sealing, cutting, forming and other processes, and can automatically complete the bag making process of PE Easy-to-peel No-residue Lid Film. Through advanced control systems and precise sensor technology, the production line can ensure that the sealing, flatness and aesthetics of each packaging bag meet customer requirements.

Unit characteristics and advantages

1. Efficient automation

The production lines and units of Changxi Packaging Technology (Yixing) Co., Ltd are highly automated. From the input of raw materials, film blowing, slitting to bag making, the entire process requires almost no human intervention, which greatly improves production efficiency and product quality. At the same time, automated production also reduces labor costs and operational risks, allowing the company to better respond to market changes and fluctuations in customer demand.

2. Precision control

On the multi-layer co-extrusion blown film production line and the fully automatic bag-making production line, the company uses advanced control systems and sensor technology to achieve precise control of the production process. These systems can monitor key parameters such as film thickness, width, temperature, etc. in real time, and automatically adjust according to the set values to ensure the stability and consistency of product quality.

3. Flexible customization

In order to meet the personalized needs of different customers, the production lines and units of Changxi Packaging Technology (Yixing) Co., Ltd are also highly flexible. Whether it is the thickness, width, color of the film or the shape, size and printing pattern of the packaging bag, the company can customize production according to customer requirements. This flexibility enables the company to better meet the diverse needs of the market and improve customer satisfaction and loyalty.

English

English عربى

عربى