How to optimize the barrier properties of five-layer co-extruded high-barrier film to meet the needs of different customers for barrier effects such as oxygen and water vapor?

Changxi Packaging Technology (Yixing) Co., Ltd., located in the beautiful Yixing, Jiangsu, is a modern packaging technology company integrating R&D, production and sales. The company has 4 advanced multi-layer co-extrusion blown film production lines. These production lines use internationally leading extrusion technology and automatic control systems, which can accurately control key parameters such as raw material ratio, temperature, pressure, etc. to ensure the uniformity and stability of each layer of film. In addition, 4 high-speed slitting units and 8 fully automatic bag production lines further improve production efficiency and product customization capabilities, with an annual output of up to 10,000 tons, fully meeting the strong demand of domestic and foreign markets.

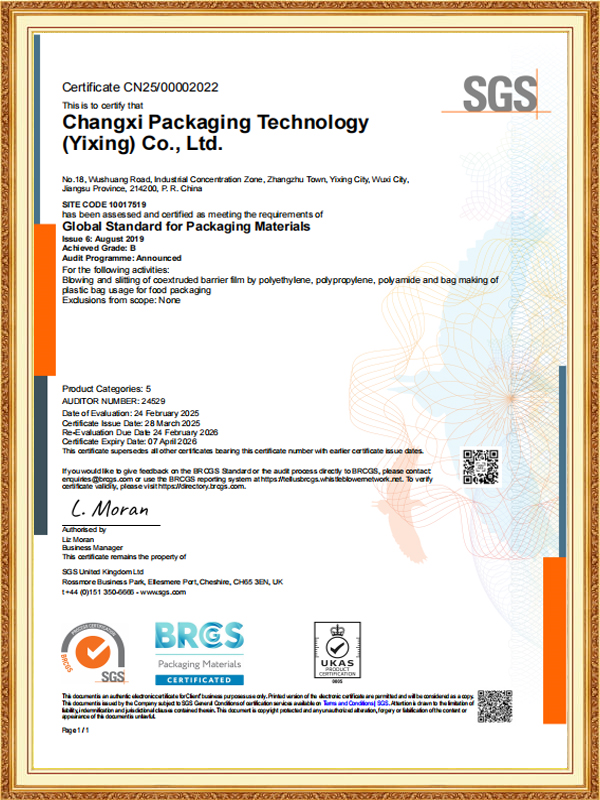

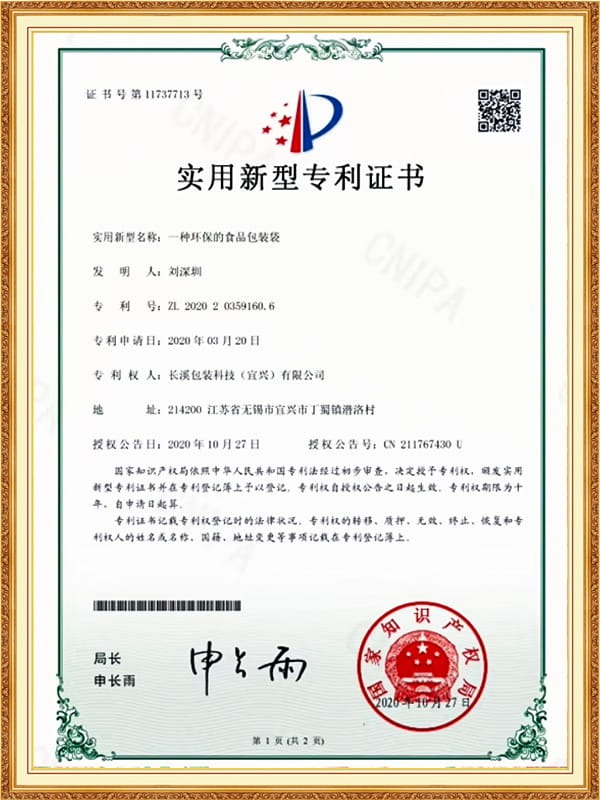

The company's quality management system strictly follows ISO standards, and each process is subject to strict quality control and testing to ensure that the products meet international safety standards. Precision testing equipment, such as gas chromatographs, moisture analyzers, etc., provide a strong guarantee for the continuous monitoring of product quality. It is this combination of software and hardware that enables Changxi Packaging's products to be widely used in food industries such as meat products, snack foods, soy products, and cream products, as well as vacuum packaging in the fields of electronic products, PCB circuit boards, textiles, down products, and chemicals, winning wide acclaim from domestic and foreign customers.

Strategies for optimizing the barrier performance of five-layer co-extruded high-barrier films

The performance optimization of five-layer co-extruded high-barrier films begins with material selection and formula design. Changxi Packaging is well aware that different customers have different requirements for barrier properties. For example, some foods require a high degree of oxygen barrier to extend the shelf life, while electronic products pay more attention to moisture and dust resistance. The company's R&D team has carefully formulated a variety of high-performance composite material formulas through in-depth research on a variety of materials such as polyethylene (PE), polypropylene (PP), ethylene-vinyl acetate copolymer (EVA), nylon (PA) and polyvinylidene chloride (PVDC). For example, using PA as a barrier layer can effectively improve the barrier performance to oxygen and carbon dioxide; while PVDC is an ideal choice for blocking water vapor due to its extremely low air permeability and moisture permeability. By precisely controlling the thickness and arrangement order of each layer of material, customized design of barrier performance is achieved.

During the co-extrusion process, Changxi Packaging adopts advanced multi-layer co-extrusion technology. By precisely controlling the temperature, pressure and flow rate of each layer of melt, it ensures that each layer of material is tightly bonded during the extrusion process to form a continuous and uniform composite film. Especially for high barrier materials such as PA and PVDC, the company introduced special co-extrusion additives to effectively improve the interfacial compatibility between materials, reduce the stratification phenomenon, and thus improve the overall barrier performance. By optimizing the film blowing process, such as adjusting the parameters such as the blowing ratio and the pulling speed, the mechanical strength and transparency of the film are further enhanced, so that the final product has good appearance and performance while ensuring the barrier performance.

In order to further improve the barrier performance, Changxi Packaging also adopts advanced surface treatment technology and coating technology. For example, coating a very thin layer of aluminum oxide or silicon dioxide coating on the surface of the film material can significantly improve the barrier ability to water vapor; and through plasma treatment or corona treatment, the adhesion between the film material and the printing ink or adhesive can be enhanced to ensure the stability and reliability of the packaging in subsequent processing. The application of these technologies not only improves the barrier effect, but also broadens the application field of the products.

Changxi Packaging is well aware that meeting the personalized needs of different customers is the key to the sustainable development of the company. Therefore, the company has established a complete customer customization service system, from material selection, formula design, process adjustment to performance testing, every step is closely communicated with customers to ensure that the final product can accurately match the actual needs of customers. Especially for customers with special barrier requirements, Changxi Packaging can provide one-to-one technical consultation and solutions, and verify the barrier performance of the product in actual application through laboratory simulation tests, so as to provide customers with more secure and reliable packaging solutions.

English

English عربى

عربى