How to choose a high-quality 7-Layer Co-extruded Barrier Film? Explore the excellent choice of Changxi Packaging Technology (Yixing) Co., Ltd

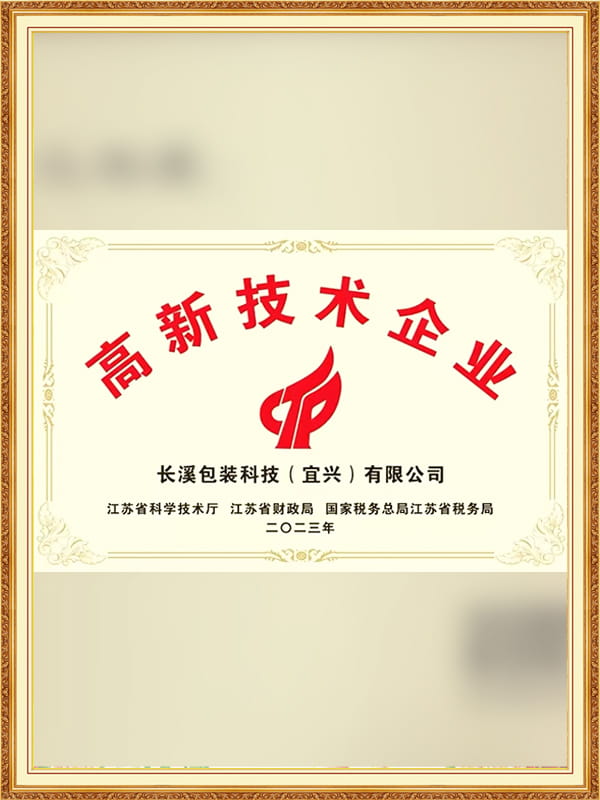

In a rapidly changing market, finding a 7-Layer Co-extruded Barrier Film that not only meets product protection needs but also has efficient production capabilities is an important issue faced by many buyers. This is not only a consideration of product quality, but also a vote of trust in the comprehensive strength and reputation of the supplier. So, how to stand out from the many choices and find the ideal partner that can not only ensure product quality but also provide a full range of services? Changxi Packaging Technology (Yixing) Co., Ltd has become the preferred choice of many buyers with its excellent technical strength, advanced production equipment and strict quality control system.

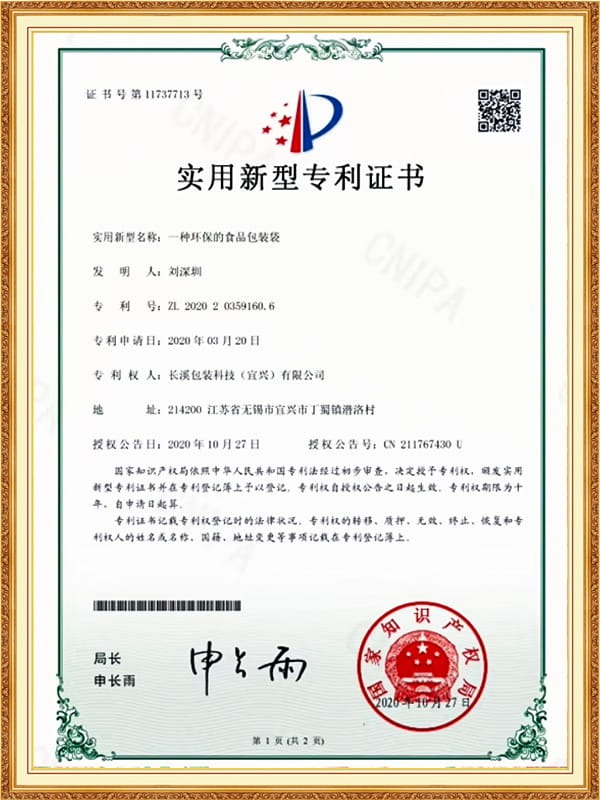

Since its establishment in 2014, Changxi Packaging Technology (Yixing) Co., Ltd has always been committed to technological innovation and quality excellence, focusing on the research and development and production of multi-layer co-extruded high barrier films and functional packaging materials. 7-Layer Co-extruded Barrier Film is the concentrated embodiment of its technical strength. Through the seven-layer co-extrusion technology, the film material achieves a perfect balance of multiple barrier effects such as oxygen, moisture, and light, effectively extending the shelf life of the items in the package and reducing the risk of deterioration, providing an ideal packaging solution for multiple industries such as food, medicine, and chemicals.

In terms of hardware, Changxi Packaging Technology (Yixing) Co., Ltd is equipped with internationally advanced production equipment, including four multi-layer co-extrusion blown film production lines, multiple high-speed slitting units, and fully automatic bag-making production lines, ensuring efficient and stable production capacity. The annual output is as high as 10,000 tons, which can not only meet the rapid delivery of large-scale orders, but also flexibly adjust the production configuration to meet the personalized needs of customers. This high degree of flexibility and production capacity is undoubtedly a great attraction for buyers who pursue supply chain efficiency and responsiveness.

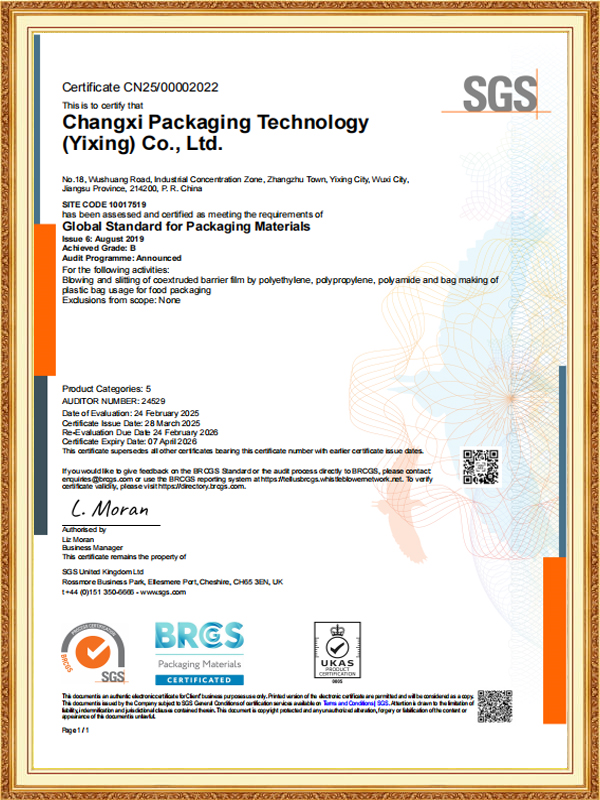

Safety and quality are key factors that cannot be ignored in purchasing decisions. Changxi Packaging Technology (Yixing) Co., Ltd has passed ISO 9001 quality management system certification, QS quality and safety certification, and strictly follows the US FDA standards to establish a complete quality control system. From raw material procurement, production and processing to finished product inspection, every step is strictly controlled to ensure that the products meet international safety standards and safeguard the safety of customers' products.

In addition to high-quality products and efficient production capacity, Changxi also provides customized packaging solutions. Whether it is specific barrier performance requirements or personalized packaging design, Changxi's professional team can work closely with customers to deeply understand their needs and provide one-stop services from design, production to logistics. This customer-centric service concept not only enhances customer stickiness, but also lays a solid foundation for long-term cooperation between the two parties.

English

English عربى

عربى