In the production process of five-layer co-extruded barrier film, how to control the melting temperature of each layer of resin and the temperature parameters of the extruder and die head?

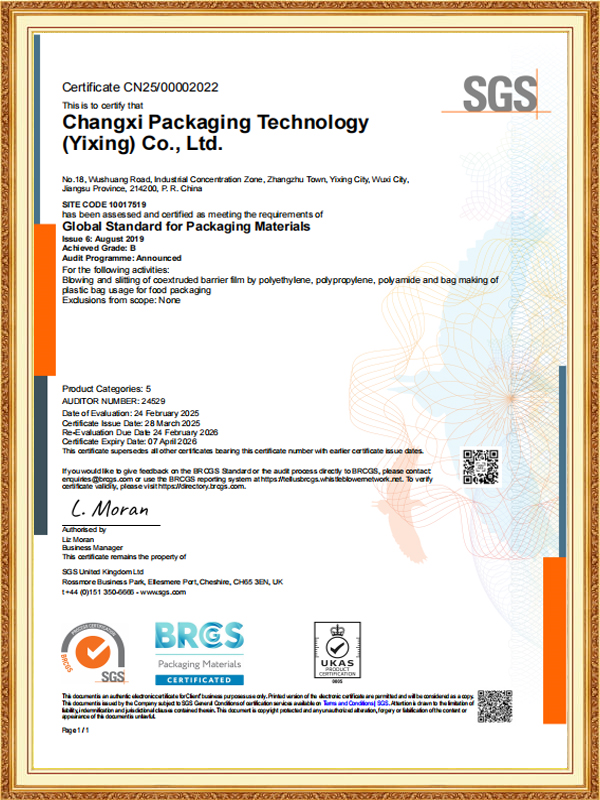

The main materials of the five-layer co-extruded barrier film include polyamide (PA), polyethylene (PE), polypropylene (PP) and special adhesive layer (TIE), each of which has its specific melting temperature and processing characteristics. Changxi Packaging Technology implements strict standards in the screening and auditing of raw material suppliers to ensure that the purchased resin raw materials are of high purity and good batch-to-batch stability, which is the prerequisite for achieving precise temperature control. The company understands its melting behavior through detailed performance testing of raw materials and provides data support for subsequent temperature setting.

Melting temperature control strategy

Layered melting temperature setting:

PA layer: Polyamide has a higher melting temperature, usually between 230-260°C, depending on its model and additive content. Changxi Company uses a precise temperature control system to ensure that the PA resin is completely melted during the extrusion process while avoiding degradation caused by overheating.

PE layer: The melting temperature of polyethylene is relatively low, generally between 120-140°C. The company precisely adjusts the melting temperature according to the specific type of PE (such as LDPE, HDPE, etc.) to ensure good fluidity while maintaining physical properties.

PP layer: The melting temperature of polypropylene is usually 160-170°C. The company will flexibly adjust the temperature according to the reinforcement level and modification of PP to ensure its stability and strength during extrusion.

TIE layer: As an adhesive layer, the melting temperature of TIE material needs to match the adjacent layers to ensure good interlayer bonding. Through in-depth material research, Changxi Company selects TIE resin with a wide processing window to ensure good bonding over a wide temperature range.

Comprehensive control: The company uses advanced temperature control systems to independently and precisely control the melting temperature of each layer to ensure that each layer of material can be fully melted during extrusion and maintain the best physical and chemical properties.

Optimization of extruder and die temperature parameters

Extruder temperature setting: The temperature setting of the extruder needs to take into account the melting characteristics of the resin, the screw design, and the extrusion speed. Changxi Company adopts segmented temperature control technology, sets multiple heating zones along the length of the screw, and gradually increases the temperature according to the flow characteristics and heating requirements of the resin to ensure uniform melting and stable delivery of the resin in the screw.

Die temperature adjustment: The die temperature is crucial to the extrusion morphology, thickness uniformity and surface quality of the film. The company accurately sets the temperature of each area of the die according to the width, thickness and material characteristics of the film to ensure that the molten resin maintains appropriate fluidity and viscosity at the die outlet, thereby obtaining high-quality, defect-free films.

Changxi Packaging Technology uses advanced automated control systems to monitor and record the temperature data of the extruder and die in real time, and automatically adjusts the output of the heating element through a closed-loop feedback mechanism to ensure that the temperature is stable within the preset range. The company is also equipped with high-precision temperature sensors and infrared thermometers to monitor the molten resin and extrusion process at multiple points, promptly detect and correct any temperature deviations, and ensure the continuity and stability of the production process.

Integration of company advantages and temperature control

Capacity and quality control: Changxi Company has sufficient capacity and an efficient operation mechanism to respond quickly to market demand while maintaining high-quality production standards. This efficient production model provides time and space for continuous optimization of temperature control, allowing the company to continuously test and optimize temperature parameters to achieve the best production results.

ERP system and supply chain management: The perfect ERP system not only optimizes production plans, but also ensures the stability and traceability of raw material supply. This helps the company to adjust temperature parameters in advance according to the characteristics of raw materials, reduce uncertainties in the production process, and improve production efficiency.

After-sales service and technical support: Changxi Company insists on seamless service and has an after-sales service team composed of technical backbones. In terms of temperature control, the team can not only provide on-site technical support, but also quickly adjust production parameters based on customer feedback to ensure that the products always meet customer needs.

English

English عربى

عربى