What is the effect of winding tension on the flatness and performance of 9-layer co-extruded high-barrier film? How does your company control the winding tension?

The effect of winding tension on 9-layer co-extruded high-barrier film

Flatness: Winding tension directly affects the flatness of the film. If the tension is too large, the film will be stretched excessively during the winding process, resulting in tensile stress. After release, the film surface may be wrinkled or uneven; if the tension is too small, the film will be easy to relax, the winding is not tight, and a ""lantern roll"" will be formed, which will also affect the flatness. Films with poor flatness will have problems such as poor lamination and printing offset in subsequent processing and use, which will seriously affect the appearance and practicality of the product.

Mechanical properties: Appropriate winding tension helps to maintain the original mechanical properties of the film, such as tensile strength, tear strength and puncture strength. Improper tension will lead to uneven stress distribution inside the film, which will affect its mechanical properties. For example, too high tension may cause the film to be overstretched in the longitudinal direction, reducing the transverse strength, and vice versa.

Barrier performance: Winding tension also indirectly affects the barrier performance of the film. Improper tension control may cause slight misalignment or peeling between film layers, destroying the tightness between multi-layer structures, thereby affecting its barrier effect against oxygen, water vapor, etc.

Heat sealing performance: Appropriate tension helps to maintain the integrity of the heat sealing layer of the film material and ensure the heat sealing strength. Excessive tension may damage the heat sealing layer and affect the heat sealing effect, while too little tension may cause the film material to slide during the heat sealing process, resulting in uneven heat sealing.

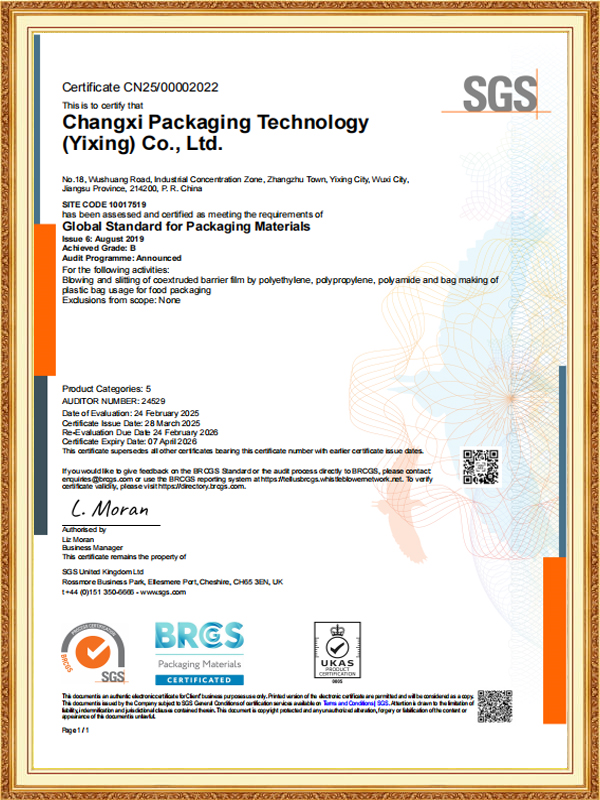

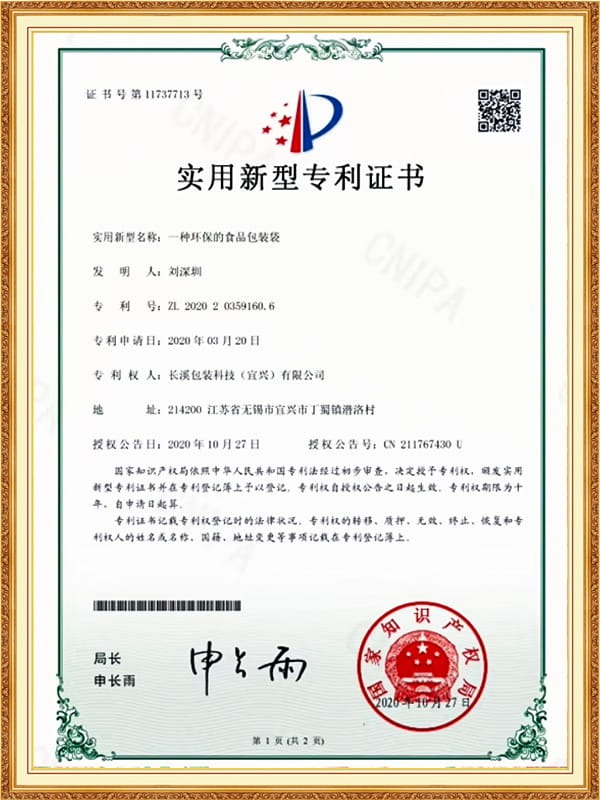

Changxi Packaging Technology (Yixing) Co., Ltd. is well aware of the importance of winding tension control. Through a series of advanced technical means and strict management processes, it ensures that each batch of 9-layer co-extruded high-barrier film can achieve the best flatness and performance.

Raw material selection and pretreatment: The company strictly implements the screening and audit of raw material suppliers to ensure that all raw materials come from suppliers with good reputation and stable quality. Before the raw materials are put into storage, strict incoming material inspection and comparison are carried out to ensure that the raw material performance meets the production requirements. The raw materials for the 9-layer co-extruded high-barrier film, especially the key barrier layer materials, are carefully selected to ensure the barrier performance of the final product.

Advanced production process design: Changxi Packaging Technology adopts advanced co-extrusion technology and precision extrusion equipment to ensure close bonding between layers and reduce internal stress by precisely controlling the extrusion speed and temperature of each layer of material. In the winding stage, the company introduced an advanced tension control system, which can automatically adjust the winding tension according to the width, thickness and production speed of the film material to ensure constant and appropriate tension.

Online monitoring and feedback adjustment: The company is equipped with a high-precision online monitoring system to monitor key parameters such as tension changes, film flatness and film thickness uniformity during the winding process in real time. Once an abnormality is found, the system immediately issues an alarm and automatically or manually adjusts the tension setting value to ensure the stability and continuity of the production process.

ERP system optimizes production processes: Changxi Packaging Technology's ERP system not only optimizes business processes such as raw material procurement, production planning, and inventory management, but also realizes real-time collection and analysis of production data. Through big data analysis, the company can accurately predict potential problems in the production process and take measures in advance to effectively avoid problems such as improper winding tension control.

Efficient sales and warehousing network: A complete sales and warehousing network ensures a rapid response from production to delivery of products. The efficient operation mechanism enables the company to arrange production quickly after receiving an order, and by optimizing the logistics route, ensure that the product is delivered to the customer within 7 days, greatly shortening the delivery cycle and improving customer satisfaction.

Seamless service and technical support: Changxi Packaging Technology has an after-sales service team composed of technical backbones, implementing round-the-clock tracking service. They not only provide professional technical support, but also visit customers regularly to collect feedback and help customers solve problems encountered in production. By establishing a customer file system, the company can provide more personalized services based on the specific needs of customers, ensuring faster and more thoughtful after-sales service.

English

English عربى

عربى