PA plastic jelly sealing vacuum packaging film has significant advantages in freshness preservation performance, which is closely related to the advanced technology and production process of Changxi Packaging Technology (Yixing) Co., Ltd. The following is a detailed analysis of its advantages:

High barrier materials: Changxi Packaging Technology (Yixing) Co., Ltd focuses on the development and production of multi-layer co-extruded high barrier films. PA plastic jelly sealing vacuum packaging film adopts this technology, which can effectively isolate air, water vapor and other external contaminants, thereby extending the shelf life of food. This high barrier is particularly suitable for products that are sensitive to oxygen, moisture and light, ensuring that foods such as jellies remain fresh.

Excellent sealing performance: PA film has good heat sealing performance and can form a tight seal during the vacuum packaging process, preventing outside air from entering the interior of the packaging and preventing bacterial growth and oxidation reactions. Combined with the high-quality production process of Changxi Packaging Technology (Yixing) Co., Ltd., these films provide a tighter seal, ensuring long-term preservation of food during transportation and storage.

Antioxidant properties: The PA film itself has strong antioxidant properties, which helps to delay the oxidation process of jelly and other products, thereby effectively maintaining its color, taste and nutritional content. Changxi Packaging Technology (Yixing) Co., Ltd uses high-quality materials that comply with FDA standards to ensure that products can meet food packaging safety standards and ensure the long-term freshness of packaged food.

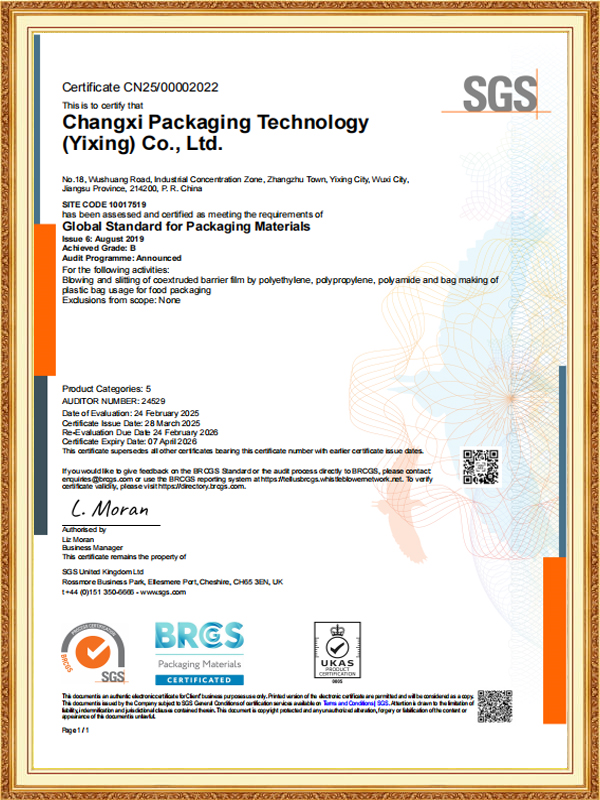

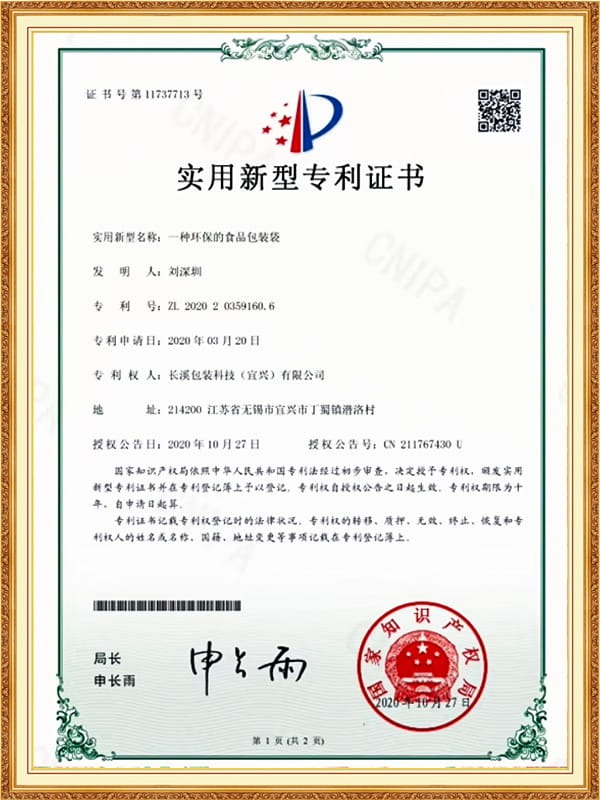

Stable quality management system: Changxi Packaging Technology (Yixing) Co., Ltd has passed ISO 9001 quality management system certification and QS quality and safety certification. Strict quality control procedures ensure the stable and stable performance of each batch of PA plastic jelly sealing vacuum packaging films. reliable. This ensures that the freshness-preserving effect of the packaging film remains consistent across different batches, meeting customer demands for high-quality packaging.

Personalized customization: Since Changxi Packaging Technology (Yixing) Co., Ltd has advanced production equipment and efficient customization capabilities, it can customize the thickness and specifications of the film according to the different needs of customers, which makes the PA plastic jelly sealing vacuum packaging film more capable It can well adapt to the freshness requirements of different products and provide better packaging solutions.

How to choose the thickness and specifications of PA plastic jelly sealing vacuum packaging film for different products?

When choosing the thickness and specifications of PA plastic jelly sealing vacuum packaging film for different products, the following key factors need to be considered:

Product characteristics and packaging requirements

Different products have different physical and chemical characteristics, which must be taken into account when choosing packaging films. For example, perishable foods or products that need to be kept fresh for a long time may require higher barrier properties. At this time, PA plastic films with multi-layer co-extrusion structures can be selected, such as the high barrier film produced by Changxi Packaging Technology (Yixing) Co., Ltd, which can effectively extend the shelf life and provide stronger moisture, oxidation and corrosion resistance.

Thickness of packaging film

Thickness is an important factor affecting the mechanical properties and barrier properties of packaging films. For high-precision vacuum packaging, such as jelly products, it is crucial to choose the appropriate film thickness. Changxi Packaging Technology (Yixing) Co., Ltd provides a variety of film thickness specifications that can be customized according to the packaging needs of different products. Thinner films are suitable for products with low sealing requirements, while thicker films provide higher puncture resistance and protection, which are suitable for products that are fragile or have high requirements for the external environment.

Barrier properties

The barrier properties of PA films are crucial to maintaining the freshness of products. For some products that are sensitive to oxygen, water vapor or light, it is necessary to choose PA films with high barrier properties. Changxi Packaging Technology (Yixing) Co., Ltd uses multi-layer co-extrusion technology to produce films with good barrier properties while ensuring appropriate thickness, which can effectively protect the contents from the external environment.

Tensile strength and puncture resistance of the film

Depending on the transportation and handling requirements of the product packaging, the tensile strength and puncture resistance of the film also need to be considered. For example, some jelly products may be hit by external forces during transportation, so it is necessary to choose packaging films with high puncture resistance and tensile strength. Changxi Packaging Technology (Yixing) Co., Ltd's production line can meet these special needs and provide packaging films with good strength and durability.

English

English عربى

عربى