Are You Seeking High-Performance Packaging? Discover the 7 Layers of Symmetrical Co-extruded Low-Temperature Film

In the ever-evolving world of packaging, where innovation and sustainability are paramount, finding the right material that balances protection, efficiency, and cost can be a daunting task. The 7 Layers of Symmetrical Co-extruded Low-Temperature Film, a revolutionary product from Changxi Packaging Technology (Yixing) Co., Ltd., a comprehensive manufacturer and supplier of soft packaging solutions integrating R&D, production, sales, and services.

Why Choose the 7 Layers of Symmetrical Co-extruded Low-Temperature Film?

Imagine a packaging film that combines the strength of multiple layers into one seamless, high-performance product. The 7 Layers of Symmetrical Co-extruded Low-Temperature Film is designed precisely for this purpose. Each layer serves a distinct function, working in harmony to provide unparalleled protection against moisture, oxygen, UV rays, and other environmental factors. This ensures that your products remain fresh, safe, and in optimal condition throughout their shelf life.

The low-temperature extrusion process allows for energy-efficient production and reduces the carbon footprint, aligning with the global shift towards sustainable practices. The film's flexibility and durability make it suitable for a wide range of applications, from food and beverages to pharmaceuticals and cosmetics.

Since its inception in 2014, Changxi Packaging Technology (Yixing) Co., Ltd. has been committed to technological innovation and excellence in quality. The company's advanced production facilities, including four multi-layer co-extrusion blown film production lines, multiple high-speed slitting units, and fully automated bag-making production lines, ensure precision in every stage of production.

With an annual production capacity of up to 10,000 tons, Changxi is well-equipped to handle large-scale orders while maintaining the highest standards of quality. The fully enclosed, high-cleanliness production workshops further guarantee a contamination-free environment, ideal for sensitive products like pharmaceuticals and baby food.

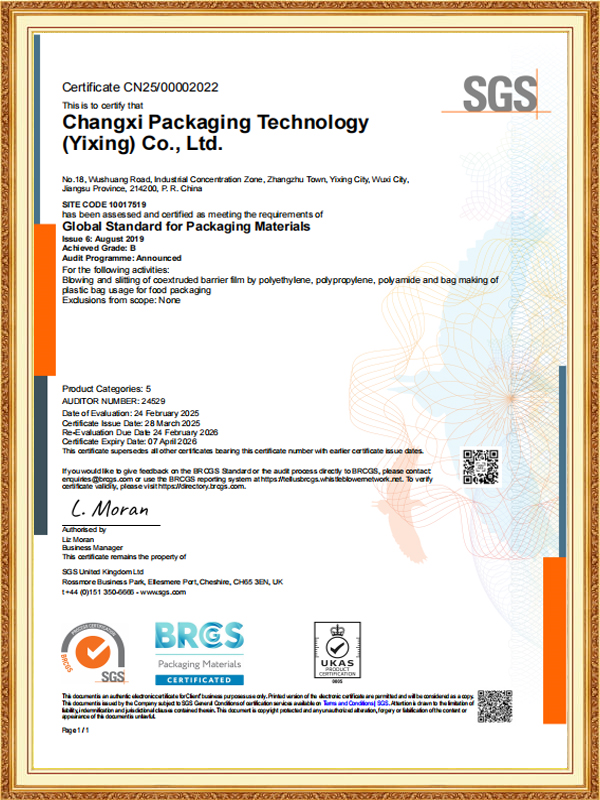

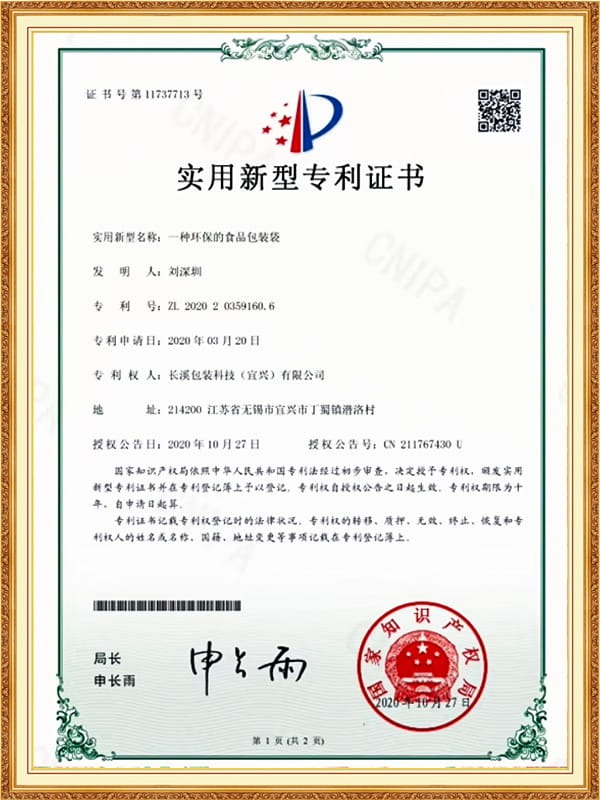

Safety and reliability are non-negotiable when it comes to packaging. Changxi Packaging Technology (Yixing) Co., Ltd. has passed ISO 9001 quality management system certification, QS quality safety certification, and complies with U.S. FDA standards. This rigorous quality management system ensures that every batch of film produced meets international safety standards, giving you peace of mind and a competitive edge in the market.

Understanding that every business has unique packaging requirements, Changxi offers personalized solutions tailored to your specific needs. From custom formulations and film thicknesses to specialized printing and branding options, the company's expert team is ready to collaborate with you to create the perfect packaging solution.

Beyond the exceptional quality of the 7 Layers of Symmetrical Co-extruded Low-Temperature Film, Changxi Packaging Technology (Yixing) Co., Ltd. stands out with its comprehensive service offerings. From initial consultations and sample testing to ongoing technical support and after-sales service, the company ensures a seamless experience from start to finish.

English

English عربى

عربى