Does the production process of transparent EVOH sealing film involve the use of environmentally friendly materials? How is its recyclability?

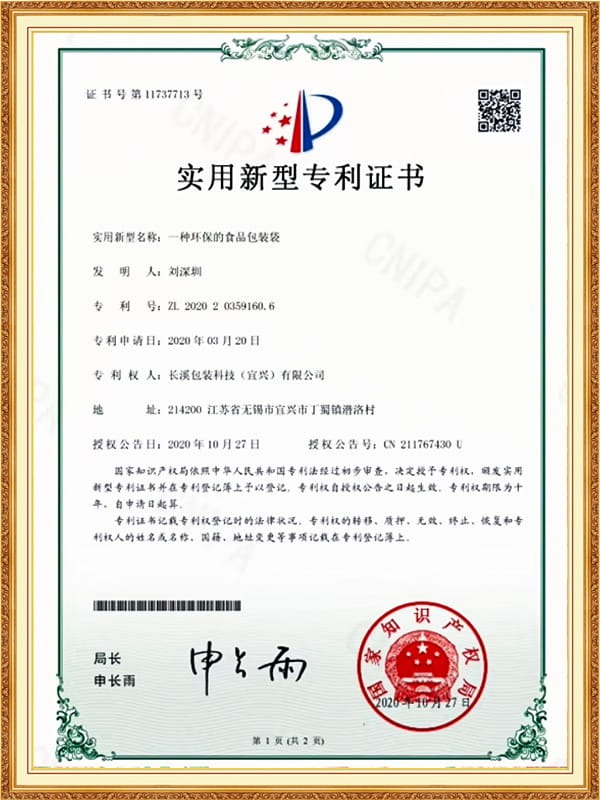

In the production process of transparent EVOH sealing film of Changxi Packaging Technology (Yixing) Co., Ltd, the use of environmentally friendly materials is highly valued. As a company focusing on the research and development and production of multi-layer co-extruded high-barrier films and functional packaging materials, Changxi Packaging has always adhered to the principles of technological innovation and high-quality production. The company is not only committed to improving the performance of packaging materials, but also pays attention to environmental protection and sustainable development, and strives to use environmentally friendly materials to reduce the environmental burden in the production process.

EVOH (ethylene-vinyl alcohol copolymer) itself is a material with excellent gas barrier properties. It can not only extend the shelf life of products such as food and beverages, but also has good recyclability. In the production process of EVOH film, the multi-layer co-extrusion technology used enables it to be co-extruded with other materials (such as polyethylene, polypropylene, etc.), making the structure of the final product more stable and the functions more diverse. Especially in terms of packaging material recycling, through a reasonable combination of materials, EVOH film can be processed together with other recyclable plastics, meeting the standards of environmental recyclability.

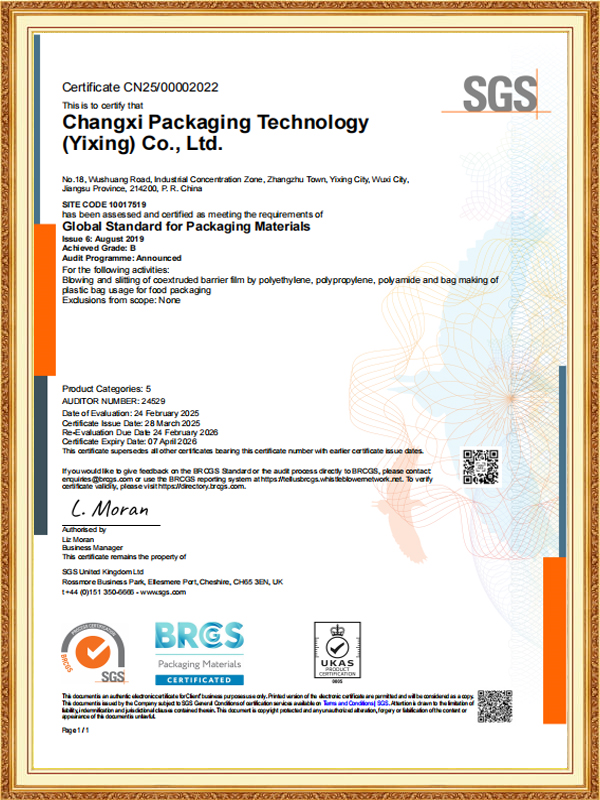

Changxi Packaging's production facilities use advanced multi-layer co-extrusion blown film production lines and fully automated production processes to ensure the efficiency and environmental friendliness of the production process. In addition, the company has passed ISO 9001 quality management system certification, QS quality and safety certification, and complies with US FDA standards to ensure product safety and environmental compliance.

Why is EVOH sealing film widely used in milk tea cup lids? What are its unique advantages?

EVOH sealing film is widely used in milk tea cup lids due to its excellent barrier properties, sealing and environmental protection characteristics, especially suitable for maintaining the quality of milk tea and extending its shelf life. As a comprehensive flexible packaging solution manufacturer, Changxi Packaging Technology (Yixing) Co., Ltd. provides ideal packaging materials for the milk tea industry with its technical advantages in the research and development and production of high barrier films.

Excellent barrier properties: One of the main advantages of EVOH (ethylene-vinyl alcohol copolymer) film is its excellent gas and water vapor barrier properties. For milk tea, a beverage that needs to maintain freshness and taste, EVOH film can effectively prevent the penetration of external oxygen and moisture and extend the shelf life of milk tea. Changxi Packaging uses its high-end production equipment and multi-layer co-extrusion blown film production line to produce EVOH film with excellent barrier effect, ensuring the freshness of the beverage in the package.

Excellent sealing: EVOH film can provide excellent sealing performance to ensure the leakproofness and stability of the milk tea cup lid. Changxi Packaging ensures the quality consistency and sealing effect of each layer of film through an automated production process, thereby achieving a perfect seal of the milk tea cup lid to avoid liquid leakage or contamination.

Environmental protection and safety: EVOH film not only performs well in function, but also meets environmental protection requirements. Changxi Packaging strictly abides by ISO 9001 quality management system certification and US FDA standards to ensure the safety and recyclability of products. This is especially important for milk tea brands and consumers who have high requirements for environmental protection.

Highly customized: Changxi Packaging has multi-layer co-extrusion technology, which can customize EVOH films with different functions according to customer needs to meet the packaging needs of various milk tea products. Whether in terms of film thickness, barrier properties or transparency, it can be adjusted according to market demand to enhance the brand's market competitiveness.

Stable production capacity: Changxi Packaging has advanced production facilities with an annual production capacity of 10,000 tons, ensuring that it can meet the production needs of large orders and provide customers with stable and high-quality EVOH film products in a timely manner. This enables the company to occupy a place in the milk tea industry and provide reliable supply chain guarantees.

English

English عربى

عربى