If you need any help, please feel free to contact us

In advanced packaging and technical film applications, multi‑layer EVOH co‑extruded high barrier top and bottom film has emerged as a core technology ...

View MoreIn contemporary food packaging system design, choosing the right materials is a multidisciplinary engineering decision that directly influences produc...

View MoreTransparent co-extruded plastic packaging film has become a significant component in modern food packaging systems. Unlike single-layer films, co-extr...

View MoreIn modern packaging systems, the coextruded top and bottom high barrier film has emerged as a critical material for enhancing product protection, shel...

View MoreComposite film aging refers to the process of combining multiple layers of films of different materials with adhesives, and then undergoing physical or chemical action for a certain period of time to completely cure the adhesive and achieve the ideal bonding strength, while ensuring the overall stability of the composite film. At Changxi Packaging Technology, this process is finely divided into the following steps:

Pretreatment: Before lamination, all raw materials must undergo strict inspection and pretreatment to ensure that there are no impurities and moderate moisture to improve the bonding effect.

Lamination process: Using advanced lamination equipment, accurately controlling temperature, pressure and speed, accurately fitting multiple layers of film with adhesive to form a composite film.

Aging treatment: This link is the core. According to the material characteristics and customer needs, select the appropriate aging method (room temperature aging or heating aging).

Performance testing: After aging, the composite film is subjected to a series of performance tests such as tensile strength, peel strength, air permeability, and oxygen barrier properties to ensure that the product meets the standards.

Slitting and packaging: According to customer needs, the composite film is slit into specified specifications, and moisture-proof and dust-proof packaging is carried out to prepare for shipment.

At Changxi Packaging Technology, the aging method of composite film is not fixed, but is flexibly selected according to specific material characteristics and customer needs:

Room temperature aging: Suitable for temperature-sensitive materials or scenes that require a long time to slowly cure to achieve the best bonding effect. The room temperature aging process is relatively gentle, which can avoid material deformation or performance degradation caused by high temperature, but it takes a long time.

Heating aging: The ambient temperature is increased by heating equipment (such as an oven) to accelerate the curing process of the adhesive. This method can significantly shorten the aging cycle and improve production efficiency, especially for urgent orders or situations where fast delivery is required. However, the heating temperature and time need to be precisely controlled to avoid overheating and material aging or poor bonding.

Aging time is another major factor in the quality control of composite films, which directly affects the curing degree of the adhesive and the overall performance of the composite film:

Too short time: The adhesive fails to fully cure, which may lead to insufficient peel strength of the composite film, easy delamination, and affect the sealing and barrier properties of the packaging.

Too long: Although a stronger bonding effect can be achieved in theory, too long aging time not only increases production costs, but may also cause unnecessary chemical reactions such as oxidative degradation due to long-term heating of the material, thus affecting the transparency, flexibility and aging resistance of the composite film.

Changxi Packaging Technology, with its in-depth understanding of the characteristics of raw materials, advanced production equipment and rich production experience, can accurately set the optimal aging time and conditions for each material to ensure that each batch of composite films can achieve the best performance state. The company also uses the ERP system to finely manage the production process, monitor the aging process in real time, and adjust parameters in time to ensure stable and controllable transparent vacuum pouch product quality.

Changxi Packaging Technology's technical advantages and service features

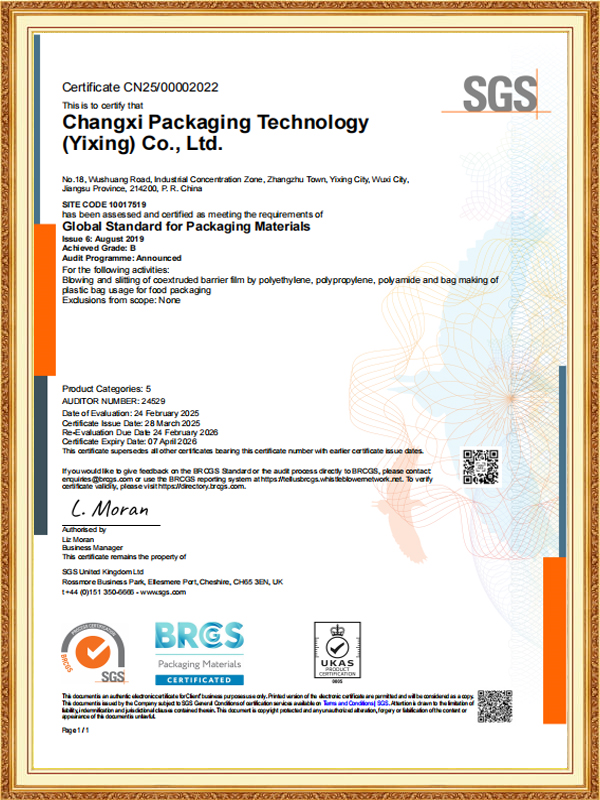

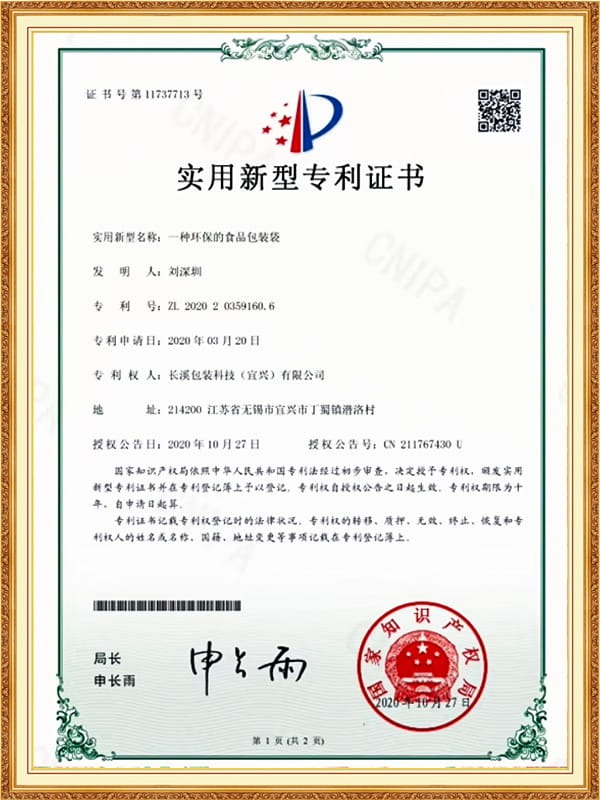

Raw material selection: The company strictly implements the screening and audit of raw material suppliers to ensure that all raw materials come from the industry's top suppliers, ensuring product quality from the source.

Efficient production process: By optimizing production process design and process control, Changxi Packaging Technology has achieved efficient and stable production, while ensuring product traceability.

Quick response mechanism: The perfect ERP system and well-planned sales and warehousing network enable the company to respond quickly to customer needs and ensure delivery within 7 days after placing an order.

Seamless service: The company has an after-sales service team composed of technical backbones, providing round-the-clock tracking services, timely visiting customers, collecting feedback, solving customer problems, establishing a regular communication and consultation mechanism and a customer file system, and is committed to providing faster and more thoughtful after-sales service.