If you need any help, please feel free to contact us

In advanced packaging and technical film applications, multi‑layer EVOH co‑extruded high barrier top and bottom film has emerged as a core technology ...

View MoreIn contemporary food packaging system design, choosing the right materials is a multidisciplinary engineering decision that directly influences produc...

View MoreTransparent co-extruded plastic packaging film has become a significant component in modern food packaging systems. Unlike single-layer films, co-extr...

View MoreIn modern packaging systems, the coextruded top and bottom high barrier film has emerged as a critical material for enhancing product protection, shel...

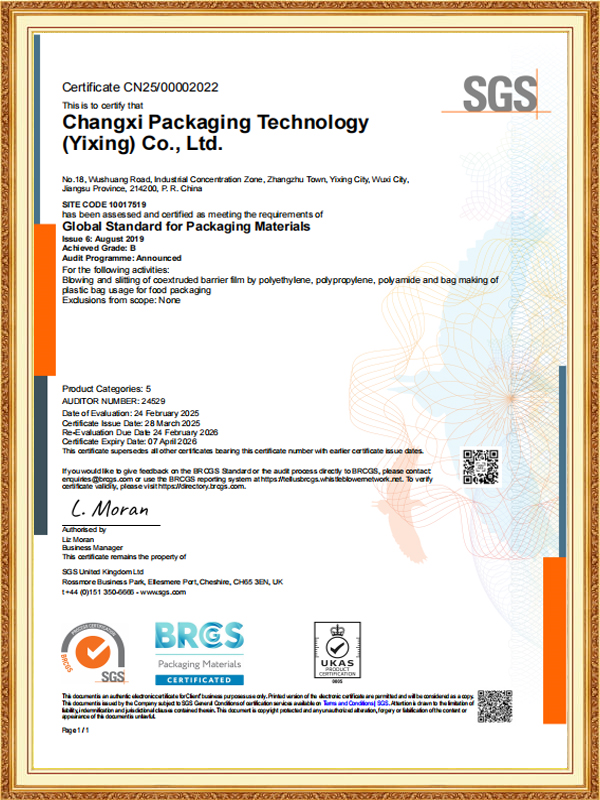

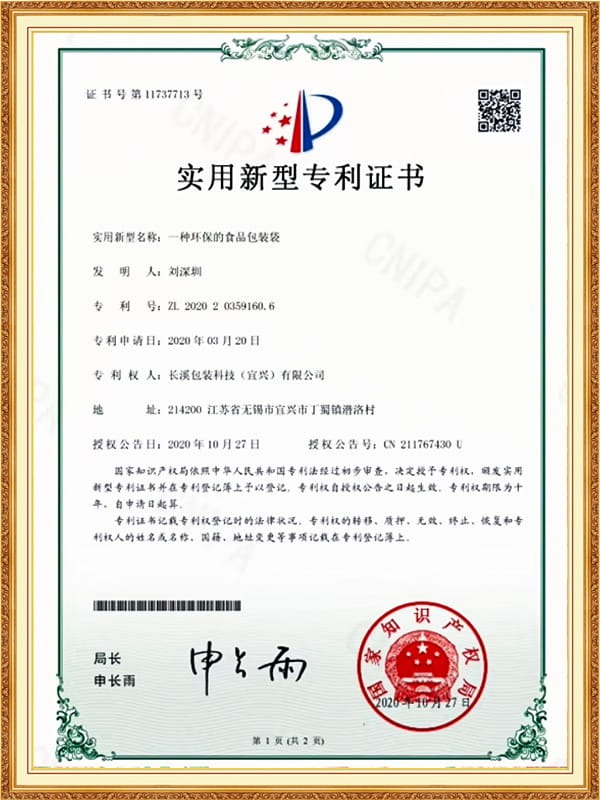

View MoreChangxi Packaging Technology (Yixing) Co., Ltd. starts from the source and strictly implements the screening and audit procedures for raw material suppliers. The company has a professional procurement team that not only conducts a comprehensive assessment of the supplier's qualifications, production capacity, and quality management system, but also goes deep into the supplier's production site to conduct on-site inspections of the production process and quality inspection methods of raw materials. Through strict control of raw materials, the company ensures that the main raw materials used in the production of co-extruded tubular film rolls - resins, additives, etc., have excellent physical properties and chemical stability, laying a solid foundation for the subsequent film blowing process.

In the incoming material inspection link, the company is equipped with advanced testing equipment, such as Fourier transform infrared spectrometer (FTIR), universal material testing machine, etc., to conduct comprehensive inspections of the chemical composition, mechanical properties, thermal stability, etc. of raw materials to ensure that each batch of raw materials meets the company's quality standards. In addition, the company has also established a raw material comparison database to compare the new raw materials with the high-quality raw materials already in the database to ensure the consistency of raw material quality.

In terms of production process design, Changxi Packaging Technology (Yixing) Co., Ltd. adopts advanced co-extrusion film blowing technology. This technology mixes resins and additives with different properties in a certain proportion through multi-layer co-extrusion to form a tubular food packaging film with a multi-layer structure. During the film blowing process, the company strictly controls the temperature, pressure, screw speed and other parameters of the extruder to ensure that the resin can be evenly melted and extruded smoothly. At the same time, the company also adopts an advanced cooling system to achieve rapid and uniform cooling of the film by precisely controlling the temperature and flow of the cooling medium, thereby effectively improving the stability of the bubbles.

In order to avoid problems such as bubble rupture and strain hardening, the company has taken the following measures in the film blowing process:

Optimize the formula: By adjusting the type and proportion of the resin, and adding appropriate amounts of plasticizers, antioxidants and other additives, the processing performance and mechanical properties of the resin are improved, the brittleness of the film is reduced, and the bubble's resistance to rupture is improved.

Accurately control the blowing ratio: The blowing ratio is one of the key factors affecting the stability of the bubble. The company ensures the uniform expansion of the bubble during the blowing process through precise control of the blowing ratio, avoiding bubble rupture caused by excessive blowing ratio.

Optimize the pulling speed: The speed of pulling directly affects the stretching degree and stress distribution of the tubular film. The company has achieved reasonable regulation of the film stretching rate through precise control of the pulling speed, avoiding strain hardening caused by too fast stretching rate.

Strengthen online monitoring: The company has installed an online monitoring system on the tubular film blowing production line to monitor key indicators such as film thickness, width, and bubble stability in real time. Once an abnormality is found, the system will immediately issue an alarm and automatically adjust the relevant parameters to ensure the stability and controllability of the production process.

Changxi Packaging Technology (Yixing) Co., Ltd. has sufficient production capacity to meet the various needs of customers. The company ensures the stable operation of the production line and the timely supply of raw materials by optimizing the production process, improving production efficiency, and strengthening equipment management. In addition, the company has also established a complete ERP system, realizing the full information management from raw material procurement, production planning, inventory management to sales and delivery, which greatly improves the company's operating efficiency and response speed.

In terms of sales and warehousing network, the company has a complete layout and can quickly respond to customer order needs. The company has also established an efficient operation mechanism to ensure delivery within 7 days after placing an order, providing customers with convenient and efficient services.

Changxi Packaging Technology (Yixing) Co., Ltd. has always insisted on seamless service and carefully built a technical backbone after-sales service team. They not only have rich professional knowledge and practical experience, but also have a high sense of responsibility and professionalism. The after-sales service team implements round-the-clock tracking service, visits customers in a timely manner, communicates feedback, and helps customers solve problems. At the same time, the company has also established a customer file system, regularly communicates and negotiates with customers, and ensures the speed and thoughtfulness of after-sales service.

During the production process of co-extruded tubular film rolls, the after-sales service team also provides professional technical support and solutions. They help customers optimize production process parameters, solve production problems, and improve product quality through field visits and data analysis of customer production sites. This all-round service and support not only enhances customers' trust and satisfaction in the company, but also lays a solid foundation for the company's continued development.