If you need any help, please feel free to contact us

In advanced packaging and technical film applications, multi‑layer EVOH co‑extruded high barrier top and bottom film has emerged as a core technology ...

View MoreIn contemporary food packaging system design, choosing the right materials is a multidisciplinary engineering decision that directly influences produc...

View MoreTransparent co-extruded plastic packaging film has become a significant component in modern food packaging systems. Unlike single-layer films, co-extr...

View MoreIn modern packaging systems, the coextruded top and bottom high barrier film has emerged as a critical material for enhancing product protection, shel...

View MoreStarting from the source, Changxi Packaging is extremely strict in the selection of raw materials. We select high-quality PA and PP resins as basic materials. These materials not only have good thermal stability and mechanical strength, but are also easy to process and form, laying a solid foundation for the subsequent heat sealing process. Through precise formula design, adjusting the ratio of PA to PP and adding appropriate amounts of heat sealing additives such as plasticizers and antioxidants, the heat sealing performance of the PA PP high-temperature film is optimized to ensure that a strong and uniform sealing layer can be formed at the heat sealing temperature.

Changxi Packaging uses advanced thermoforming equipment to precisely control parameters such as heating temperature, mold design and molding pressure to keep the PA PP thermoforming film in the best physical form and dimensional stability during the thermoforming process. The precise control of this step is crucial for the subsequent heat sealing process because it directly affects the contact area and uniformity of the heat sealing interface, which in turn affects the heat sealing strength.

In the heat sealing process, we have introduced advanced technologies such as high-frequency induction heat sealing and ultrasonic heat sealing, which can achieve rapid and precise heating of local areas of the food thermoforming film, thereby forming a high-strength seal in a short time. By optimizing the combination of heat sealing temperature, pressure and time, we ensure that the heat sealing interface is fully fused in the molten state to form a continuous and dense sealing layer, effectively preventing the occurrence of leaking seals.

Changxi Packaging has fully implemented the ERP management system and networked tracking information of the production process, which means that every link from the storage of raw materials to the delivery of finished products is strictly monitored and recorded. In terms of heat sealing strength control, we have set up a special testing laboratory and use advanced tensile testing machines to test the heat sealing strength of heat-sealed samples to ensure that each batch of film meets the established quality standards. In addition, we also regularly calibrate and maintain production equipment to ensure its accuracy and stability and avoid fluctuations in heat sealing strength caused by equipment factors.

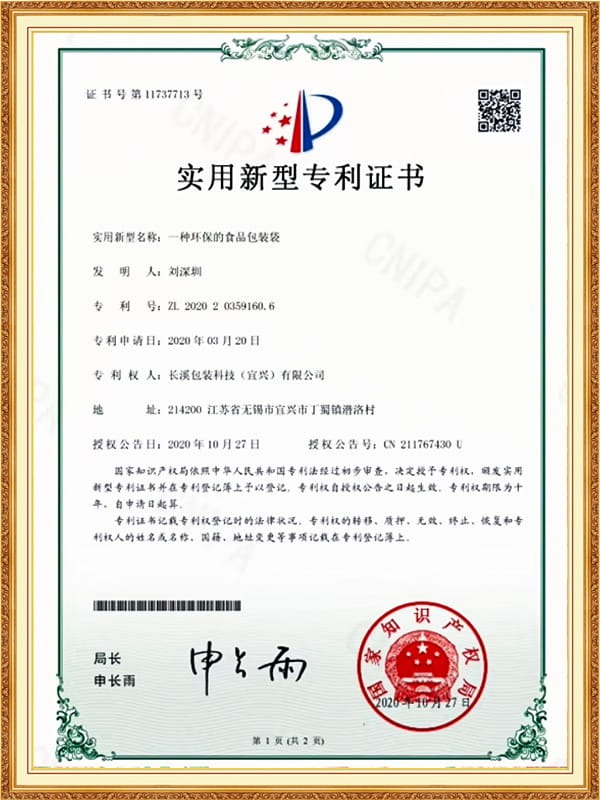

Technological innovation is the core of Changxi Packaging's competitiveness. We have a research and development team composed of material scientists, engineers and technical experts who are constantly exploring new material formulations, process technologies and quality testing methods to meet the growing demand for food packaging and market challenges. For example, by developing new heat sealing additives, we can further reduce the heat sealing temperature and reduce energy consumption while improving the heat sealing strength and sealing reliability. In addition, we are also exploring the application of bio-based and degradable materials to meet the market demand for environmentally friendly packaging.

Changxi Packaging knows that each customer's food packaging needs are unique. Therefore, we provide one-stop customized services from product design, material selection, process optimization to finished product testing. Our technical team will work closely with customers to deeply understand the characteristics and packaging requirements of their products and jointly develop the most suitable thermoforming high-temperature film solutions. We also provide detailed technical support and after-sales service to ensure that customers can get timely and effective solutions when they encounter any problems during use.